Welcome!

First of all,if you are looking for any IS standard - Click here

Here are some test details performed by us,read it so you can understand better, this way you can improve your quality in production and have best of raw materials.

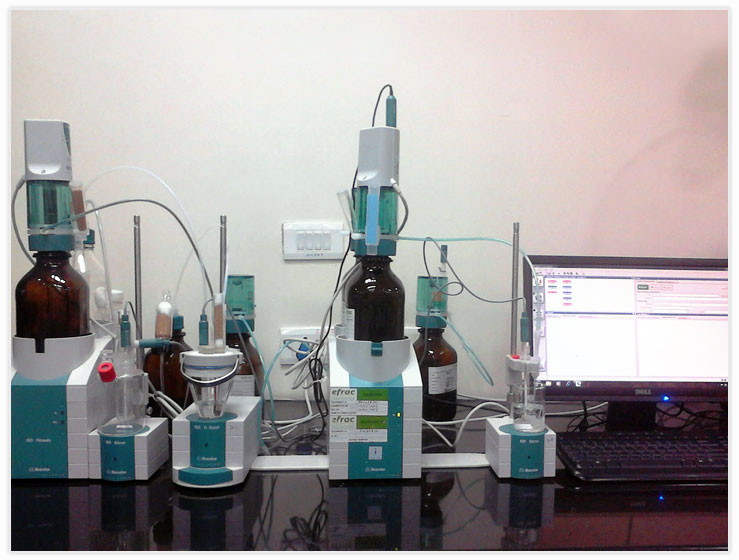

Chemical Testing

.

.

.

● Spectro Testing

These instruments meet your requirements of fast and urgent analysis of ferrous and non-ferrous metals and alloys in shortest span of time i.e. 30 seconds. Highly accurate and dependable instruments which are specially tailor- made to suit requirements of our customer, calibrated with reference materials traceable to international standards. Capable of Analysis of All Ferrous Metals & Non-Ferrous Metals by Spectrometry, including Copper, Aluminium, Nickel, Cobalt and Titanium Alloys.

However We don't recommend spectro testing as it is software based and chemical component given by spectro machine are surface based results,there are some controversy over this topic from so far...● Wet Analysis

Wet Chemical analysis excludes all techniques that use instrumentation for quantitative analysis. Gravimetry (in which a chemical species is determined by weighing) and Titrimetry (which involves volume measurement of a liquid reactant) are two procedures that we use in our laboratory to perform classical chemistry.

Mechanical Testing

.

.

.

● Tensile Testing

A tensile test measures the resistance of a material to a static or slowly applied force. A machined specimen is placed in the testing machine and load is applied. A strain gage or extensometer is used to measure elongation. The stress obtained at the highest applied force is the Tensile Strength. The Yield Strength is the stress at which a prescribed amount of plastic deformation is produced. Elongation describes the extent to which the specimen stretched before fracture. Information concerning the strength, stiffness, and ductility of a material can be obtained from a tensile test. Variations of the tensile testing include; Room Temperature, Low Temperature, Elevated Temperature, Shear, Temperature and Humidity, Combined Tension and Compression, Through Thickness, True Strain, Notched Tensile values.

● Bend

Bend testing is a procedure to determine the relative ductility of metal that is to be formed usually sheet, strip, plate or wire. The specimen is usually bent over a specified diameter mandrel. The four general types of bends are free bend, guided bend, semi-guided bend, and wrap around bend.

● Compression

Compression testing is a method for assessing the ability of a material to withstand compressive loads. This test is commonly used as a simple measure of workability of metal, particularly in forging and similar bulk deformation processes. Engine mounts, bolster springs, cast products, and similar components are tested to determine load versus displacement.

Testimonials

Nayan Patel

Have got excellent experience being client of accurate. They are best in the business.

nay*****@gmail.com | 98*****615Hi-end Equipments